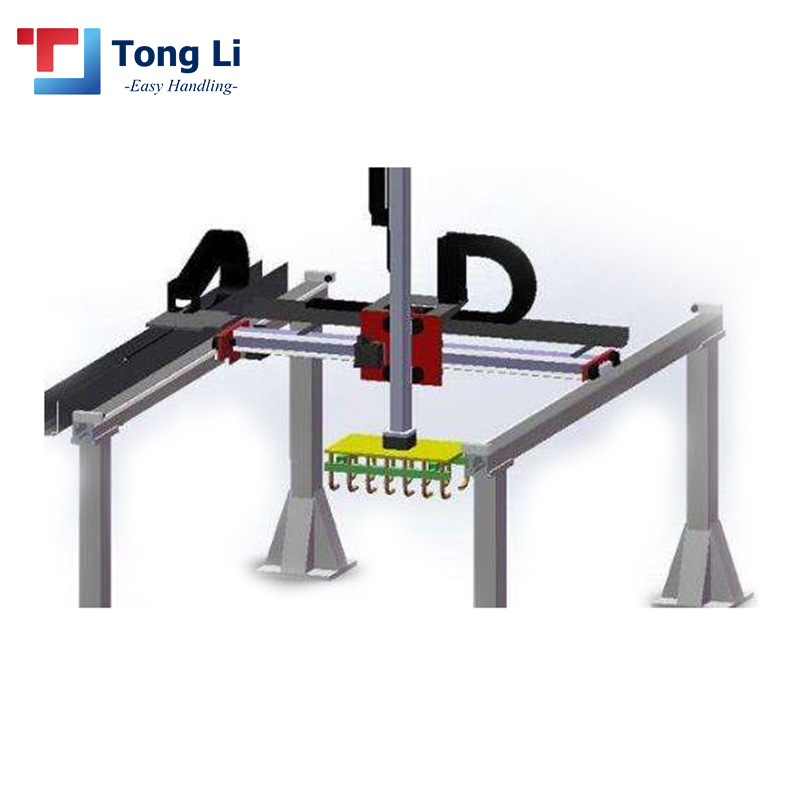

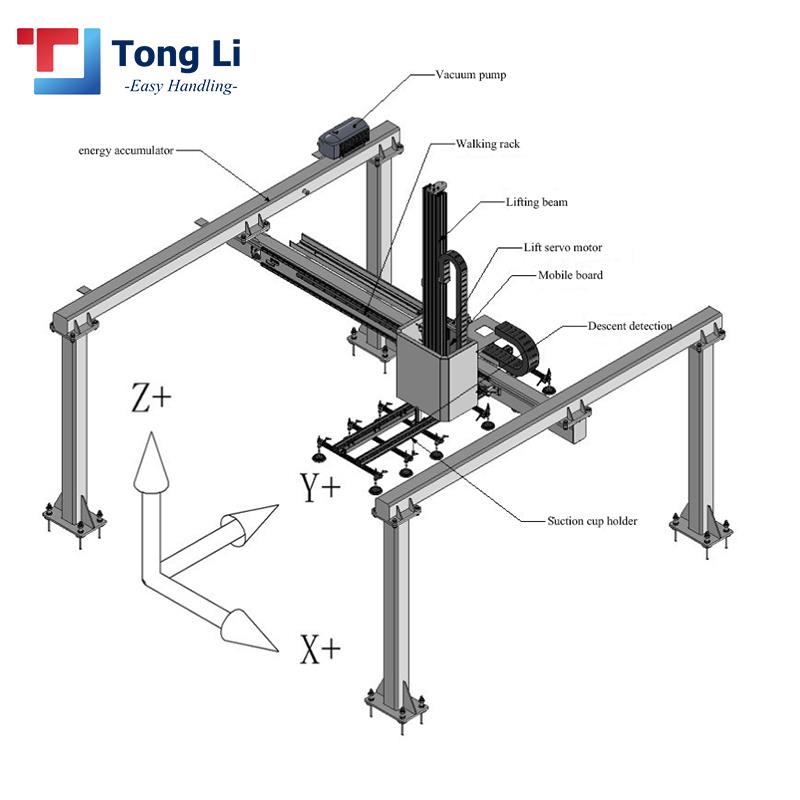

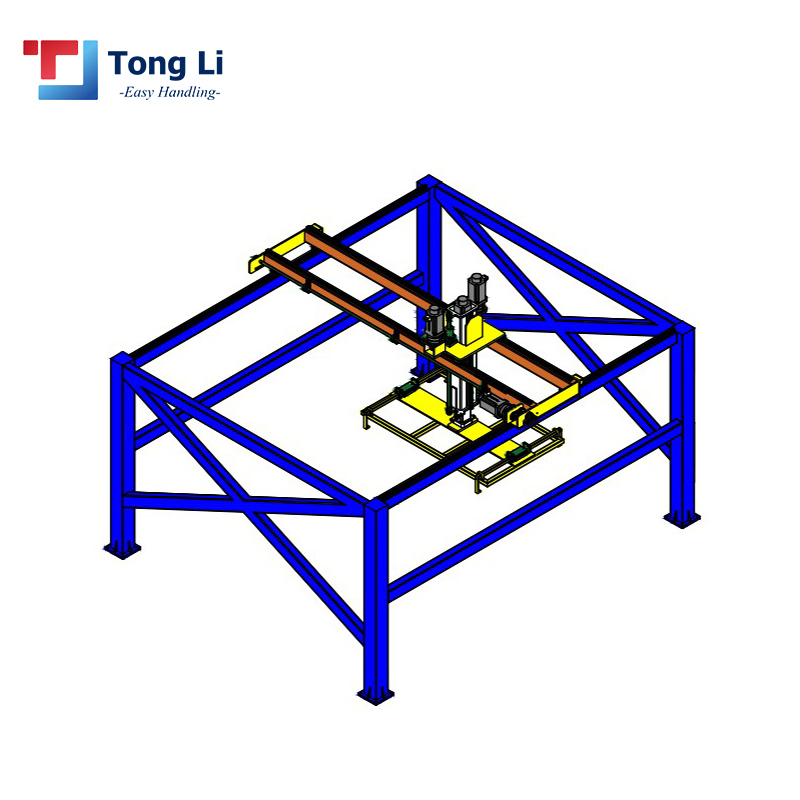

Gantry Robot

Manipula na truss yana amfani da fasahar sarrafawa mai hade, wanda ya dace da lodawa da sauke kayan aikin injina da layukan samarwa, jujjuyawar kayan aiki, juyawar kayan aiki, da sauransu. A lokaci guda, tsarin matsewa da sanya kayan aiki mai inganci yana ba da daidaitaccen tsari don sarrafa robot ta atomatik, kuma daidaiton matsayi na maimaitawa yana tabbatar da babban daidaito, Ingantaccen inganci da daidaito na samfuran rukuni.

Manipula na truss inji ne da zai iya tara kayan da aka ɗora a cikin akwati ta atomatik (kamar kwali, jaka mai laushi, bokiti, da sauransu) ko wani abu da aka naɗe kuma aka shirya a cikin kayan yau da kullun. Yana ɗaukar kayan ɗaya bayan ɗaya a cikin wani tsari kuma yana shirya su a kan fakiti. A cikin wannan tsari, ana iya tara kayan a cikin yadudduka da yawa kuma a tura su waje, zai zama da sauƙi a je mataki na gaba na marufi da aika zuwa ma'ajiyar kaya don ajiya ta hanyar forklift. Manipula na truss yana fahimtar sarrafa aiki mai hankali, wanda zai iya rage yawan aiki sosai kuma ya kare kayan sosai a lokaci guda. Hakanan yana da ayyuka masu zuwa: hana ƙura, hana danshi, hana rana, hana lalacewa yayin sufuri. Saboda haka, ana amfani da shi sosai a cikin masana'antun samarwa da yawa kamar sinadarai, abin sha, abinci, giya, filastik don tara siffofi daban-daban na samfuran marufi ta atomatik kamar kwali, jakunkuna, gwangwani, akwatunan giya, kwalabe da sauransu.

1. Masana'antar sassan motoci

2. Masana'antar abinci

3. Masana'antar sufuri

4. Sarrafawa da ƙera

5. Masana'antar taba da barasa

6. Masana'antar sarrafa itace

7. Masana'antar sarrafa kayan aikin injina

| Mai sarrafa truss ta atomatik | |||||

| Load(kg) | 20 | 50 | 70 | 100 | 250 |

| Gudun layi | |||||

| X axis(m/s) | 2.3 | 1.8 | 1.6 | 1.6 | 1.5 |

| Axis Y(m/s) | 2.3 | 1.8 | 1.6 | 1.6 | 1.5 |

| Axis na Z(m/s) | 1.6 | 1.3 | 1.3 | 1.1 | 1.1 |

| Faɗin aikin | |||||

| X axis(mm) | 1500-45000 | 1500-45000 | 1500-45000 | 1500-45000 | 1500-45000 |

| Axis Y(mm) | 1500-8000 | 1500-8000 | 1500-8000 | 1500-8000 | 1500-8000 |

| Z axis(mm) | 500-2000 | 500-2000 | 500-2000 | 500-2000 | 500-2000 |

| Daidaiton matsayi mai maimaitawa (mm) | ±0.03 | ±0.03 | ±0.05 | ±0.05 | ±0.07 |

| Tsarin shafawa | Man shafawa mai mai da hankali ko mai zaman kansa | Man shafawa mai mai da hankali ko mai zaman kansa | Man shafawa mai mai da hankali ko mai zaman kansa | Man shafawa mai mai da hankali ko mai zaman kansa | Man shafawa mai mai da hankali ko mai zaman kansa |

| Saurin sauri (㎡/s) | 3 | 3 | 3 | 2.5 | 2 |